Q-Shield™ insulation solutions are used on generators and various types of standing equipment of all sizes. Solutions are available for both generators used inside facilities and as well as units that are used permanently in the field.

Engine & exhaust heat control are critical areas in controlling and managing high levels of heat We will insulate the key components to provide appropriate levels of heat protection.

Typical Applications:

- Air Intake Conduit

- Exhaust Piping

- Manifold Shielding

- Turbo Shields and Covers

- Muffler

Case Study

| Specifications | |

|---|---|

| Problem Statement | Excessive heat from the exhaust pipe was affecting the performance of the air intake system and causing harm to users |

| Component Shielded | Exhaust Pipe |

| Test Conditions | On Field and Test Cell |

| Pre Q-Shield™ Temperature on Exhaust Pipe | 550 ºC 1022 ºF |

| Post Q-Shield™ Temperature on Exhaust Pipe | 90 ºC 194 ºF |

| Number of Layers of Heat Shield | 4 |

| Thickness | 16 mm 0.63 in |

Solution

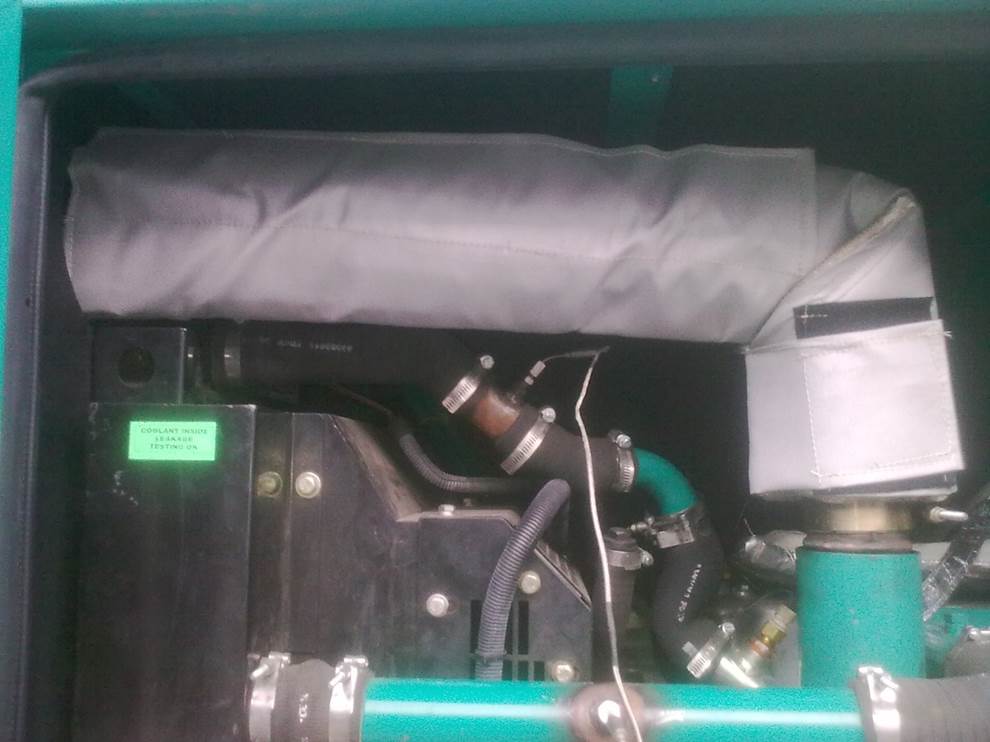

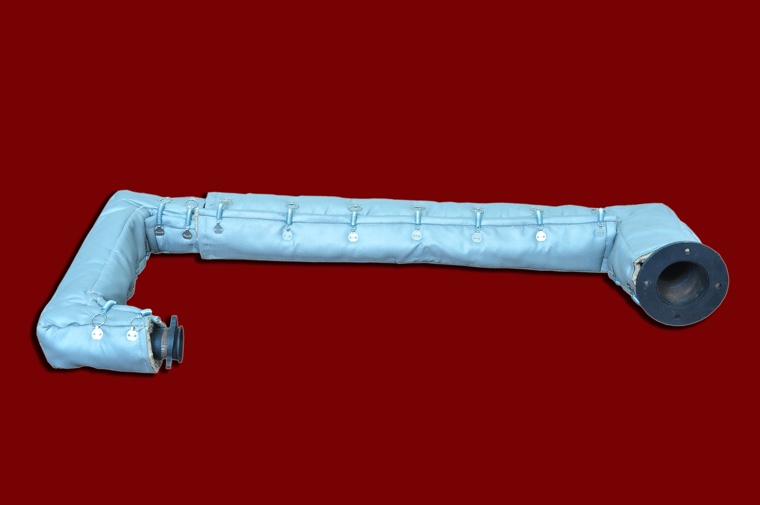

Thermal insulation on generator sets is essential for reliable performance and long-lasting operation. At QUSA Thermal, Inc., we manufacture insulating systems that meet specific requirements based on each genset configuration, taking into account factors such as the heat profile, the dimensions, and whether it is installed indoors or outdoors. One example is the exhaust pipe insulation shown in the photograph. In this situation, excessive heat from the exhaust pipe was impacting the performance of the air intake system and causing harm to users. Since a cooler air intake system results in better genset performance and reduced risk of worker injury, we leveraged our Q-Shield™ technology to design a solution.

Our design engineers developed a test cell to analyze the heat levels and determine the shielding requirements. Results of our analysis showed that the exhaust pipe was reaching temperatures of up of 550 ºC (1022 ºF). To address the issue, we manufactured a custom a Q-Shield™ exhaust pipe insulation that featured four layers of heat shielding material and includes a durable cover fabric that protects users from burns if they accidentally come into contact. Once we installed the cover, fired up the genset, and recorded the temperatures, results showed that temperature of the exhaust pipe dropped down to 90 ºC (194 ºF).

In addition to improving the operation of the air intake system, our custom solution reduced the risk of worker injury and protected sensitive genset components from excessive heat exposure that could cause them to fail prematurely. The exhaust pipe insulation is easy to remove and reinstall for servicing. Our Q-Shield™ technology played a vital role in improving the performance and extending the service life of this genset.

Contact us directly to learn more about our custom thermal insulation solutions for generators and gensets or to make an inquiry.

QUALITY DELIVERED

QUSA Thermal is a global leader in providing removable and reusable custom insulation solutions. Serving customers across the globe our product is engineered to the highest standards to ensure the most reliable product available in the market today.

Our production facility is ISO 9001:2015 and IATF 16949:2016 certified. Our team has experience across a wide variety of industries and applications. We have extensive real-world experience producing all types of designs and configurations.

The Q Shield™ insulation product can be applied to any piece of equipment. These shields can be easily removed and reapplied as application use and maintenance operations dictate.

IATF 16949: 2016 Certified

IATF 16949: 2016 Certified

UL 2200 Certified

UL 2200 Certified